Watching a mezzanine grow can look like magic … a sleek structure rises from the ground, ready to double or triple the size of a warehouse and hold the most sophisticated equipment.

With Hi-Level Mezzanines there is, of course, a great deal of science behind it, conceived and executed by a team of qualified structural engineers using an innovative digital design process and advanced solutions.

Here we lift the lid on the process, to reveal the science behind the structure.

We have taken as an example our work for Granger Hertzog, a company hiring furniture and props to the film industry.

Ideal design solution

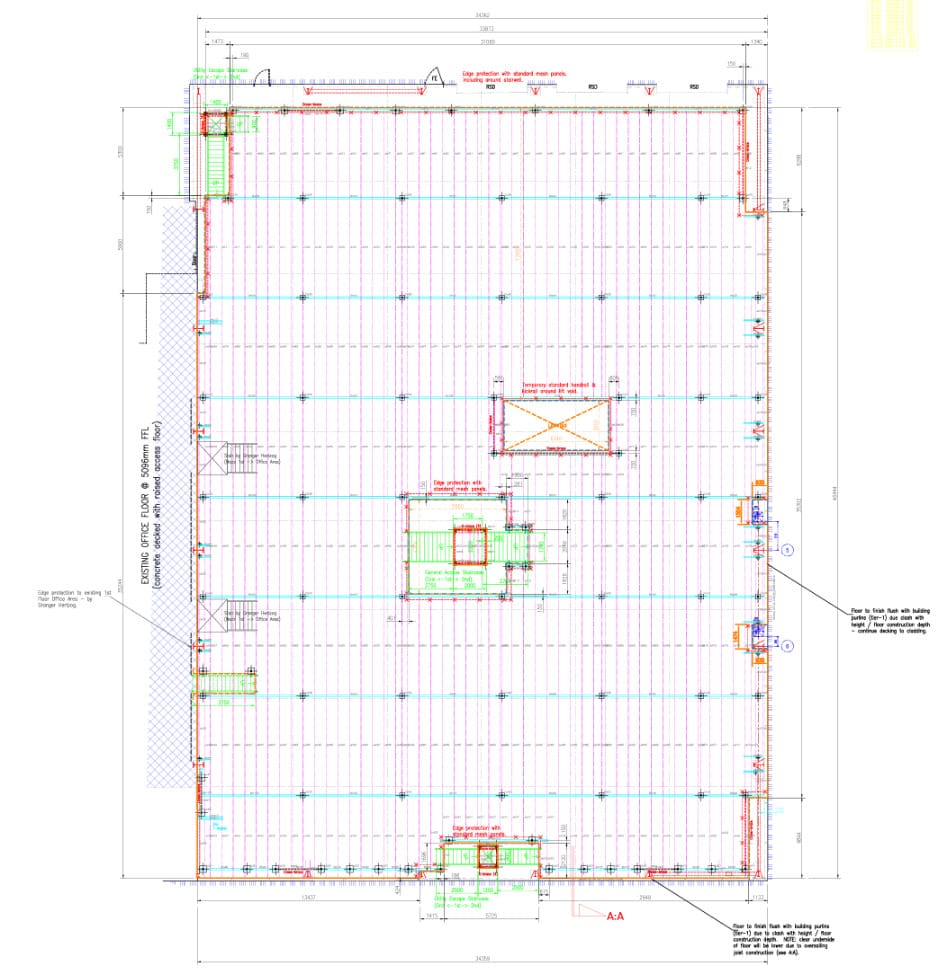

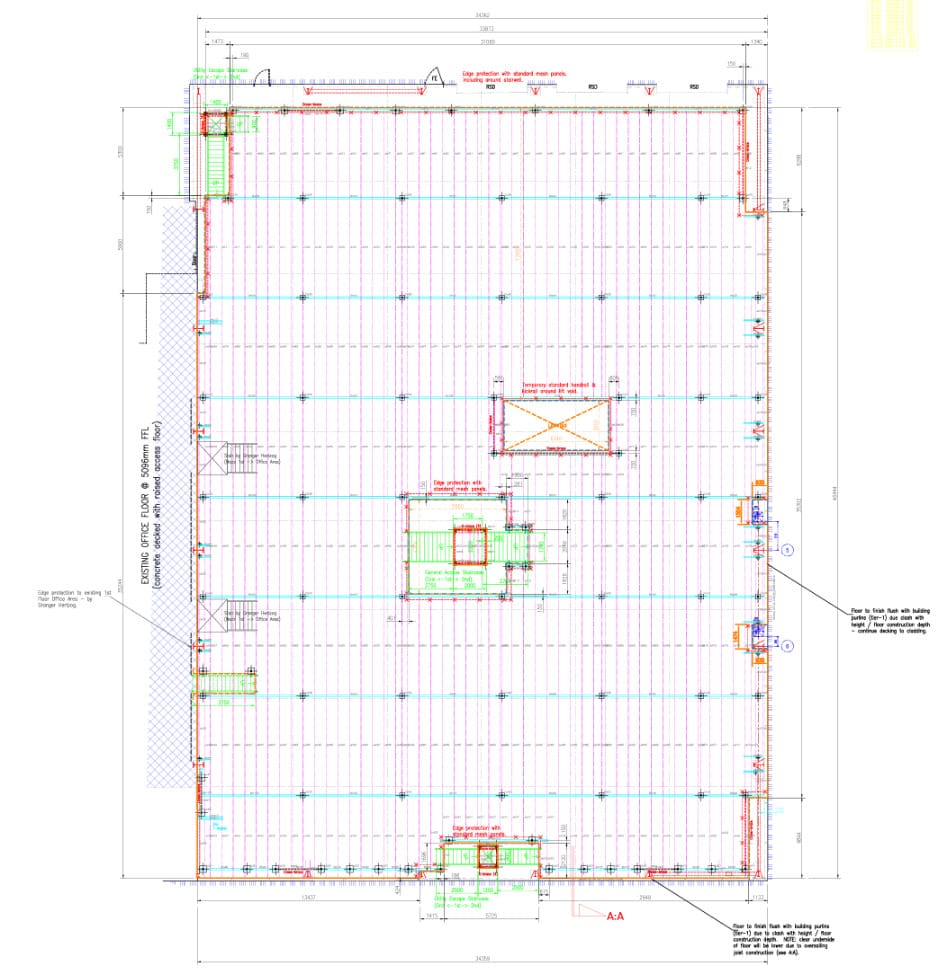

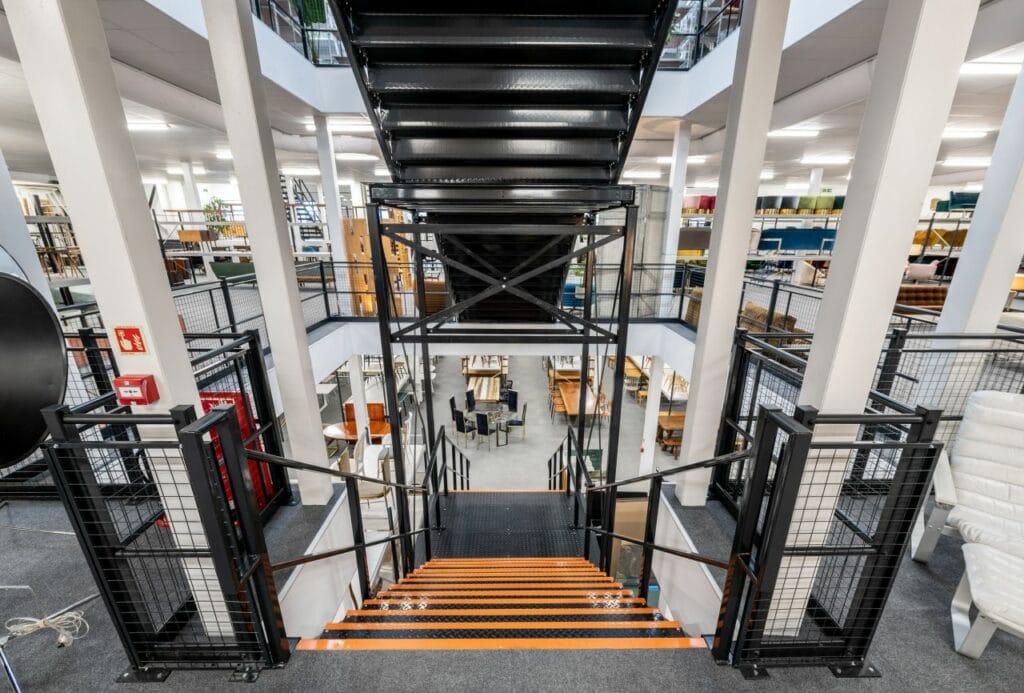

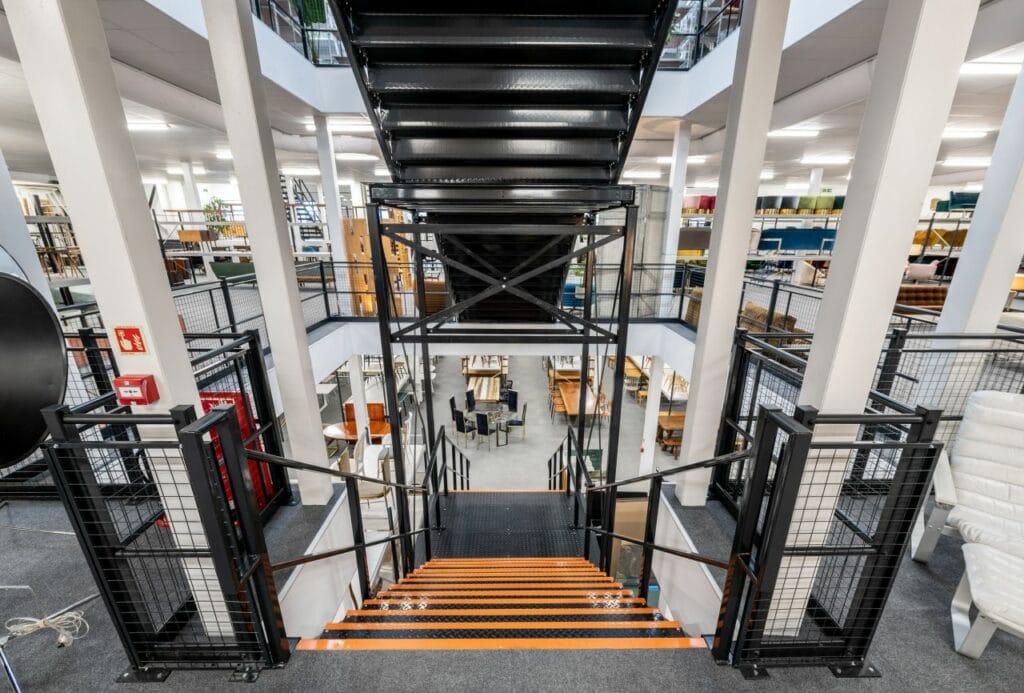

For Granger Hertzog we built a two-tier mezzanine providing 1400m² of floor area per tier, offering as much open space as possible for clients to browse the company’s wide collection of eclectic pieces from around the world.

Criteria were discussed and honed during many design meetings so we could execute the brief to the company’s exact requirements. Over nine months we perfected the ideal design solution for the new showroom; provided a detailed layout which complied with all the relevant building regulations and would minimise any safety risks; carried out structural investigations to make sure the floor slab could support the column loads from the mezzanine floor; and built the two tiers of mezzanines, all maximising space for employees while improving the efficiency of Granger Hertzog’s operations.

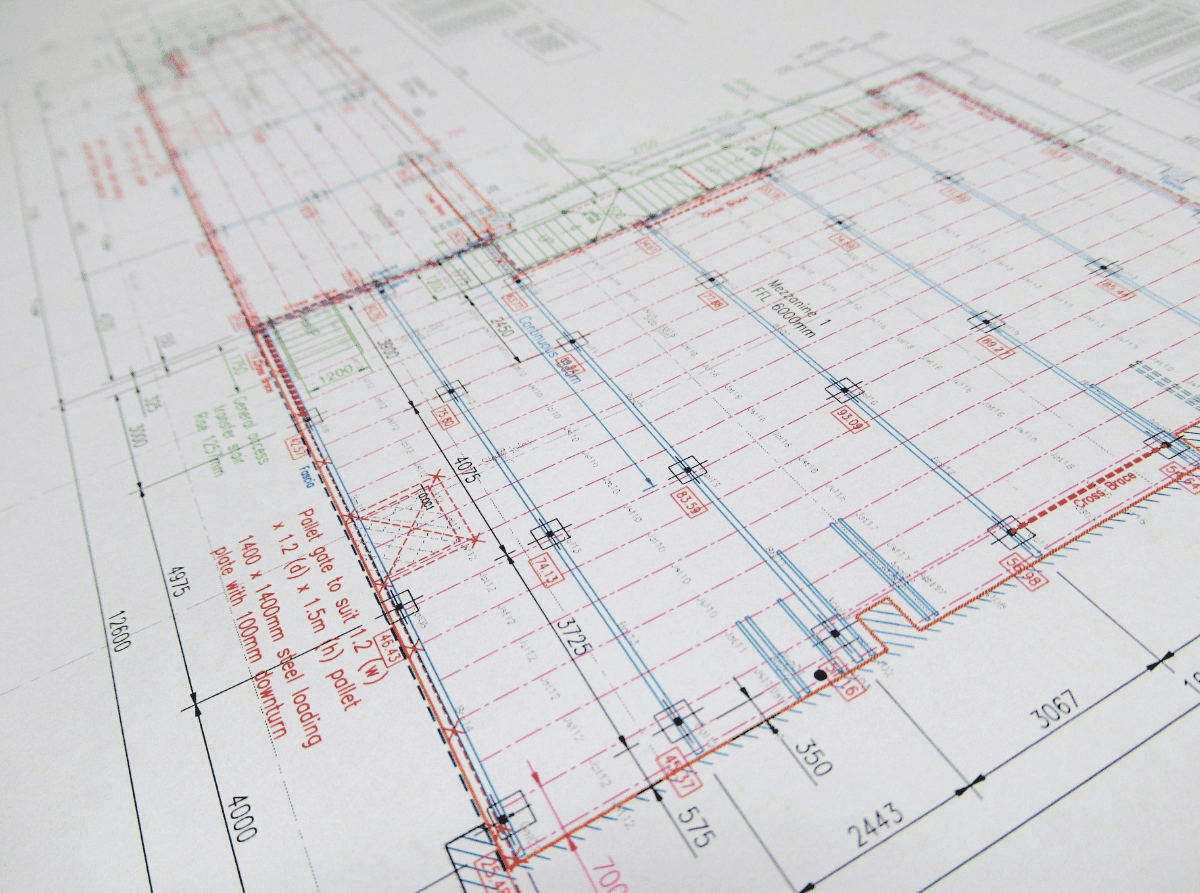

Design Protocol

Our Design Protocol is followed in every instance. The steps include Design Philosophy & Assumptions, Design Loads, Member Checks (such as columns, beams, joists, stairs, handrail, connections, bracing, baseplates and decking), Frame Stability and Connection Design, all in accordance with BS EN 1993-1-1:2005.

Hi-Level Sales Director Chris Baxter, a qualified structural engineer, explains: “When I arrive on a site to meet a client the first thing I do is find out exactly what they want to use their mezzanine for. We can then establish the load capacity. Then we need to understand what the ground floor operation is going to be, because customers want as few columns as possible. But the fewer columns, the heavier the steel and higher the steel content, which increases the cost. We look at the ground slab and the weight it can take then calculate the column grid. From this basis we design the mezzanine, at every stage liaising with the client to make sure they are getting the best solution for their needs.”

Regular communication

The finished showroom for Granger Hertzog captured the company’s vision for a modern open-plan concept full of light and character. The larger premises provided ample space to display its extensive collection across three floor levels. Throughout the build, Hi-Level Mezzanines made weekly site visits and such regular communication resulted in both parties being extremely pleased with the finished look.

Hi-Level Mezzanines provides mezzanine floors of the highest quality in the industry, yet remaining competitively priced thanks to the expertise of our team of qualified structural engineers, innovative digital design process and advanced solutions.

For 30 years we have been creating space for amazing things to happen. Contact us today for more information at [email protected] or call 01730 237 190.