Mezzanine floors offer fantastic solutions for businesses looking to initiate, or expand on, their automation processes. Adding a single or multi-tiered mezzanine floor maximises use of overhead space to accommodate automation, conveyor systems and robotics, while other areas can be used to store, manage and dispatch products.

Warehouse automation is forecast to grow at 19% a year between 2024 and 2027, according to Interact Analysis’ Warehouse Automation report. Another eye-watering figure is that the market is expected to reach $41 billion by 2027, according to LogisticsIQ. Businesses need to adapt at pace to keep up with the transformations happening across the industry.

As Paul Stone, Chief Operating Officer at DHL Supply Chain UK&I told Logistics Manager: “We expect the implementation of robotics and automation in warehouses to continue escalating as the industry navigates the demand for faster deliveries, ongoing labour shortages and the continued growth of e-commerce.”

Just as automation plays a key role in supporting warehouse capacity and optimising performance, so do mezzanines.

Here are our 5 top benefits of mezzanines for automation.

- The only way is up. Mezzanines allow your automation to expand upwards rather than being limited to the ground floor. You can add multiple tiers of automation in your existing building, future proofing your premises as technology and automation evolve. Mezzanines can be reshaped, extended and reduced quickly as required. Warehouse tech innovations already making waves include Radio Frequency Identification Systems (RFIDs) to quickly identify and track items as they move through the warehouse, allowing staff to locate products faster, and predictive analytics to forecast future demand for products. New technologies are making warehouses smarter, more efficient and more cost-effective, and mezzanines provide the space to take advantage of these benefits.

- More space, less hassle. It’s no secret that pressure from rivals in a highly competitive sector is often behind a push for change – whether it is leading the way or playing catch-up. Businesses introducing automation under pressure from competitors find that mezzanines are quicker and easier to install than moving to new premises, with all the costs, effort and inconvenience that hunting for a new building involves. Mezzanines mean more space and less hassle.

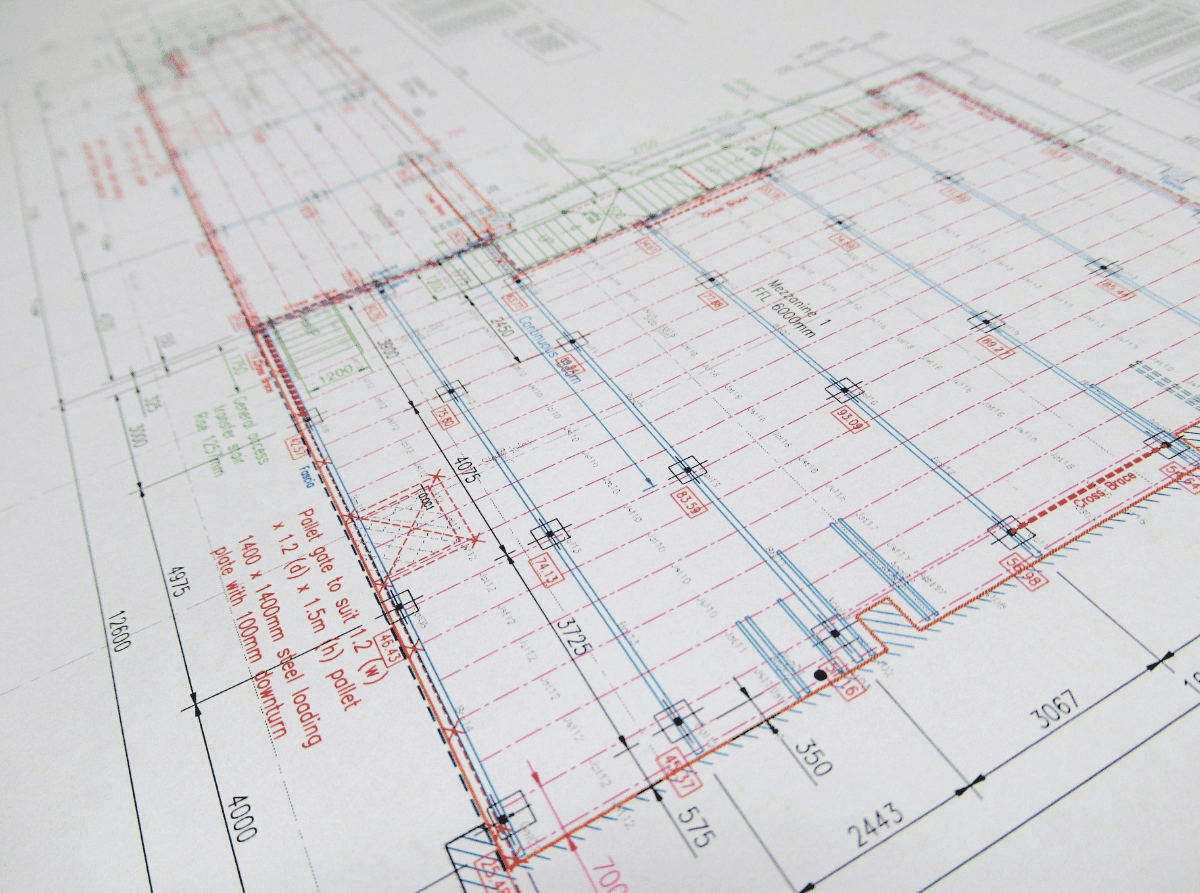

- Taking the weight. Hi-Level Mezzanines can design mezzanine floors for most static and dynamic loads produced by automated equipment. Our automation constructions can withstand the substantial load placed upon them by heavy-duty equipment such as conveyor systems and robotic machinery. For Next, one of the UK’s best-known fashion retailers, we designed and installed a two-tier, 24,000m² mezzanine floor for a new distribution centre near Rotherham (photo above). It can bear a load of 6kN/m² to support a specialist conveyor-belt sortation system that transports goods around the warehouse in preparation for dispatch to stores and mail-order customers. The sortation system was installed above the mezzanine floor on all three levels, while cable trays from the external electricity supply were channelled under the floor to feed specific areas. The use of additional joists at key sections of the floor required the specialist knowledge that comes from our 30-year pedigree.

- Ready for robotics. Amazon’s Director of Robotics Fulfilment Scott Anderson has predicted that fully automated warehouses will be common within the next 10 years, with robots and advanced AI packing orders in a fraction of the time it takes humans. Many companies begin with one or two robots and as their business grows, add more. Robots are eminently scalable and so are mezzanines, which can be installed just as easily. Hi-Level Mezzanines are proud to be market-leading innovators in this sector and in 2023 launched a unique product, our robot-ready mezzanine floor tile Hi-Tile.

- Versatility every time. As well as mezzanine decking to hold conveyors and robotics, mezzanines are also frequently installed as access walkways and maintenance platforms to service automated machinery. Another example of flexibility is that we can design steel columns in configurations to suit each client’s automation layout. ASOS, a global leader in online retail, is delighted with the three-tier mezzanine floor we installed to create space for several new conveyor systems, provide additional storage and streamline the automation process inside its distribution centre. The new floors totalling 6,000m² were specifically designed to connect to an existing structure. Hi-Level’s Project Manager explained that the four-month project “was multi-phased and involved working within a busy warehouse environment. Over the 14 phases we faced considerable challenges that we ultimately overcame with careful consideration and planning.”

If you’d like to know more about how mezzanine floors can help your business reap the benefits of automation, get in touch at [email protected] or call 01730 237 190.