When two thirds of companies say they’re planning to invest in something in the next year, it’s a sign that big changes are afoot.

In this case it is a move towards automation across the warehouse, fulfilment, production and distribution sectors.

But we are not surprised, because we know from our clients that two major trends are underway: businesses installing mezzanines to provide more space without moving premises, and introducing robotics to future-proof their operations.

Which is where Hi-Level Mezzanines comes in, with the UK’s most innovative and cost-effective robot-ready mezzanine flooring.

Our new hybrid mezzanine flooring system consists of a robust interlocking 7mm textured PVC floor tile with an anti-slip surface.

Quick to install, these panels are exceptionally hard wearing to prevent indentations caused by robots running 24/7 along the same routes.

“The tile option is a great way to create a perfect floor very, very quickly”

Simon Houghton, Geek Plus robotics, specialising in Goods-to-Person automation

Creating cost-effective robot-ready mezzanine flooring

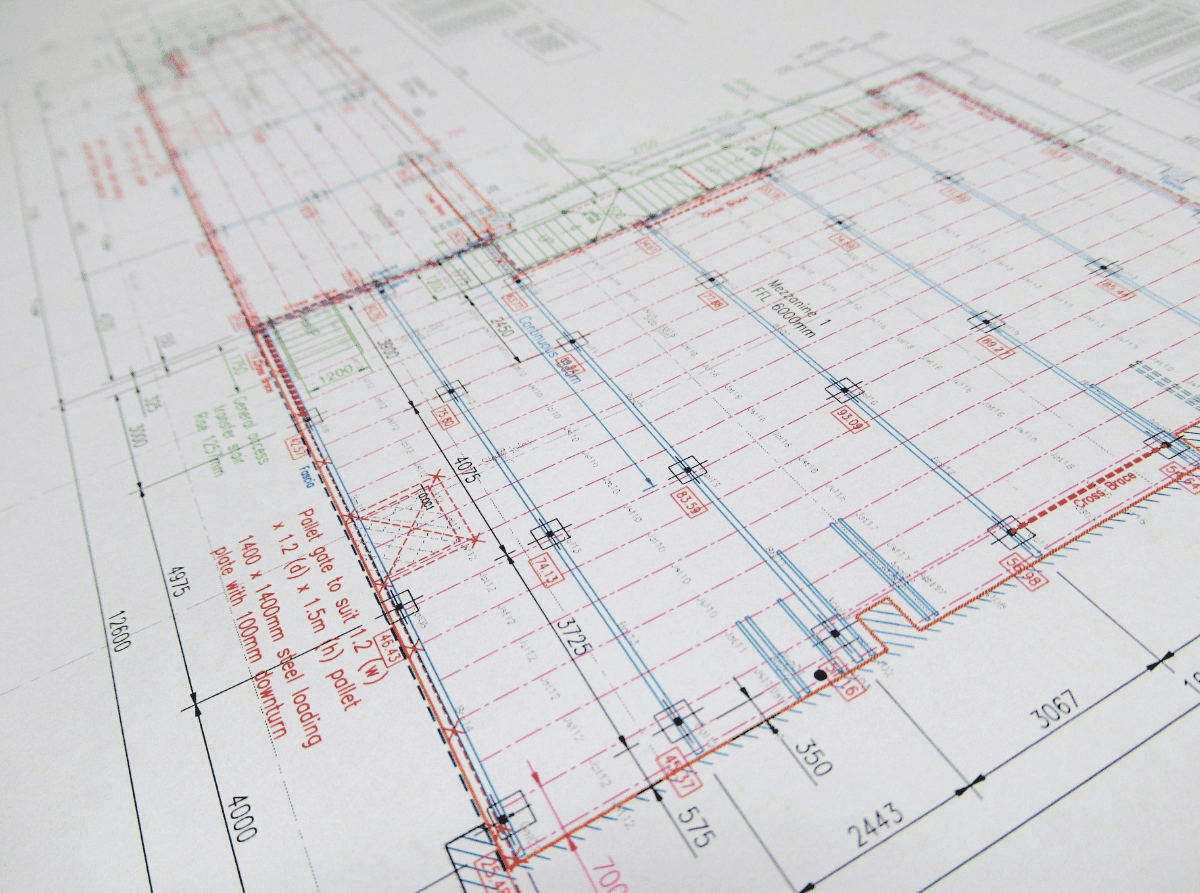

Hi-Level Mezzanines’ structural engineers created this system by:

- deciding that products already on the market were too expensive

- innovating to create a cost-effective alternative

- testing our solution with a global robot provider in China and a leading supermarket chain in the UK

- then acquiring sole rights to sell it for use with robotics on mezzanines in the UK and mainland Europe.

Our engineering expertise and agility in doing so has never been more important.

An escalating need

According to research recently published by Warehouse magazine, 68% of warehouse, fulfilment, production or distribution companies have plans to invest in automation in the next 6 to 12 months. It reported that the “tremendous effect” of COVID-19 has spurred them to use robotics as a way to insulate them from future disruption. Firms also highlighted the benefits for their employees, including less repetitive manual work and the opportunity to upskill.

Automation is increasingly being used to assist with managing the movement, storage and sorting of warehouse inventory, with many retail giants leading the way.

With the Black Friday/Cyber Monday weekend generating an estimated £5.7 billion in online sales, this phenomenon is only going to grow.

Many of the retailers we have worked with are all ahead of the game in realising that, as industrial premises grow in size and mezzanines are increasingly used to optimise the available space, their floors need to be robot-ready.

What makes our mezzanine flooring robot-ready?

- Excellent durability and slip resistance

- Helps reduce indentations from regular moving loads

- Electro-static resistance required by robots

- Any damaged tiles can be replaced without disrupting the rest of the floor

- Choice of 11 colours so contrasting colours can be used to highlight particular areas of the floor

- Simple to clean and maintain.

It also aligns with our environmental policy, as the tiles are made out of 100% recyclable PVC with any surplus material converted into more tiles.

Our robot-ready mezzanine flooring meets industry criteria for minimal slopes, steps and joints; it prevents the indentations that happen when inferior surfaces are used; and it can be half the price of the alternative option of using steel plates on timber board, especially with steel prices escalating.

Multi-level mezzanines

As robots work seamlessly with each other on multiple levels, moving in and out of goods lifts or passing goods from one floor to another floor down chutes, a multi-layered mezzanine can be a brilliant space-saving and cost-effective investment.

Our structural engineers are highly experienced and able to design solutions to withstand any load or usage requirement, including heavy conveyor systems and robotic machinery.

Hi-Level Mezzanines has the expertise for the longevity, durability and safety of mezzanine solutions to fit your requirements.

For more information on how to optimise your space with a mezzanine solution, please contact us at [email protected] or call 01730 237 190.