When one mezzanine is not enough, Hi-Level Mezzanines has the structural engineering and project management skills to install multi-level mezzanines to give you full use of your space. Two to four tiers are usual, although we have installed five levels in one instance.

We have just been commissioned to design and build a multi-tier mezzanine on three levels for a large High Street retailer to cater for several types of automation. The retailer’s new sortation facility will have a mixture of robots, conveyors and shelf storage to cope with its growing online orders.

Three examples of our multi-tier mezzanines

- For online retail giant ASOS we installed a three-tier mezzanine to create space for several new conveyor systems, provide additional storage and streamline the automation process inside its current distribution centre. Our project management allowed the company to maintain production during the building work to ensure demand continued to be met.

- For Granger Hertzog, a company hiring furniture and props to the film industry, we built a two-tier mezzanine providing 16,000ft² of floor area per tier, offering as much open space as possible for clients to browse a wide collection of eclectic pieces from around the world.

- For global transport and logistics company DSV Butler & Willow we designed a three-tier mezzanine area for handling goods and supporting lightweight conveyor systems.

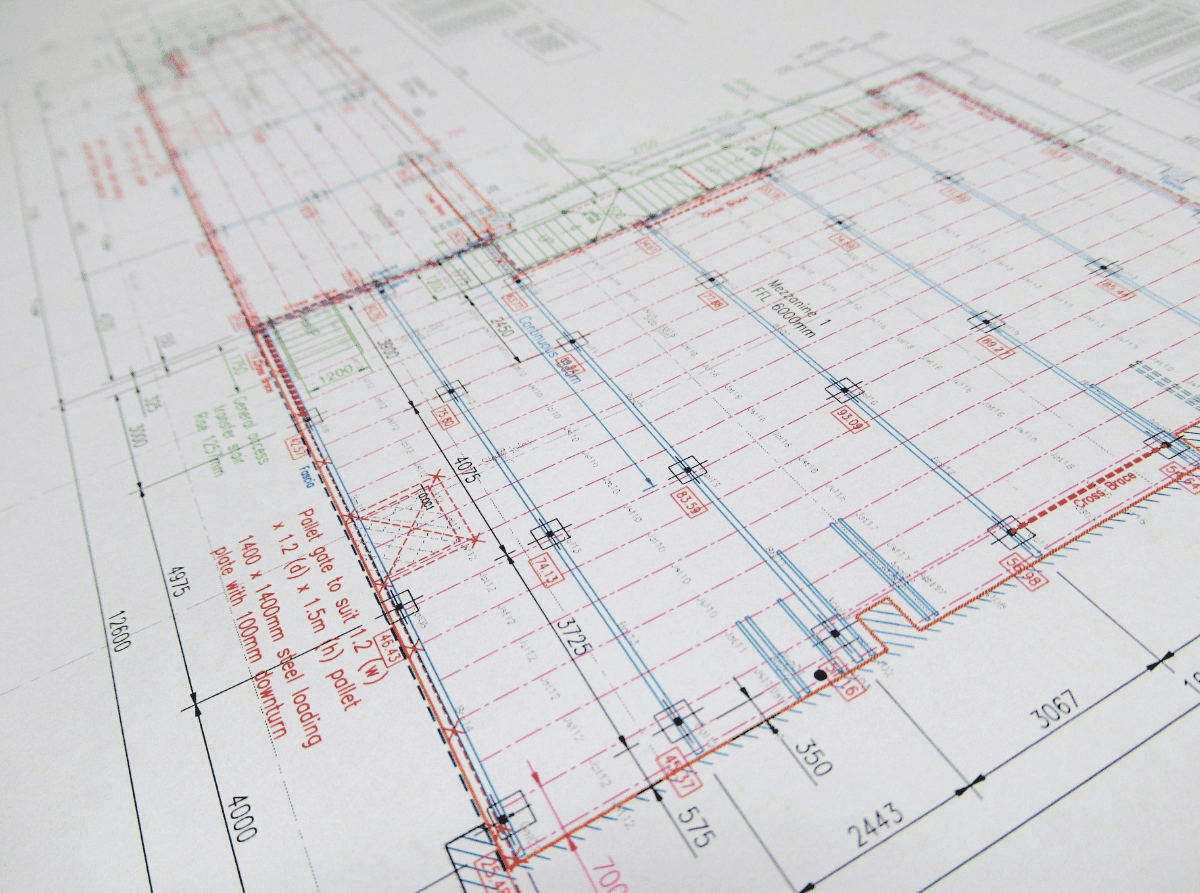

Considerations for installing multi-tier mezzanines

- Slab: very few slabs can take the load required for multi-tier mezzanines so we carry out localised strengthening by installing mini piles.

- Design: we value-engineer our designs by looking at different combinations of multi-storey construction – for example, different columns and load combinations between levels – to come up with the best value.

- Decking: each floor can have a different flooring, such as robot-ready or heavy-duty composite.

- Access between floors: this can be through staircases, goods lifts and/or conveyor systems (including voids if needed).

- Fire safety: our mezzanines are fire-rated with cladding or sprinkler systems included in the design.

- People and plant: multi-tier mezzanines are generally larger projects than single tier and as such require much larger installation teams and closer site management. The type of plant used depends on variables such as loading, heights and spans together with build programme, which are all key factors when selecting the right equipment.

- Height of edge protection: this can vary, with 2m mesh installed at a Tesco facility to prevent accidents.

Project management on site

Project management and installation

We build multi-tier mezzanines from the top down. First we put in the steelwork at the top then infill the joists that the decking sits on. We then move down to the next level and do the same before moving down again. The decking team arrive and install the flooring from the bottom up to enable streamlined handover to our clients, who can bring follow-on trades in to work on the completed lower levels.

Future-proofing with a multi-tier mezzanine

If clients believe they may need an extra tier as their business grows, we advise them to install it at the same time as the first level – because once the first tier is fully operational it invariably proves too disruptive to add a second.

The key is to install the skeleton steelwork – columns for the second tier with minimal steelwork, or even all the steelwork in place – ready for it to be decked and occupied in the future.

Hi-Level Mezzanines provides mezzanine floors of the highest quality in the industry, yet remaining competitively priced thanks to the expertise of our team of qualified structural engineers, innovative digital design process and advanced solutions.

For 30 years we have been creating space for amazing things to happen. Contact us today for more information at [email protected] or call 01730 237 190.