With booming investment in the automotive sector, expanding companies are making smart use of their space to improve productivity and meet customer demand.

The automotive industry is the jewel in the crown of the UK manufacturing sector, employing 800,000 people and generating £13.3 billion a year for the economy.

It attracted £20bn of private sector commitment in 2023, more than in the previous seven years combined (£16bn). Investments are being made across the supply chain in battery and electric car manufacturing, lithium mining and in research and development, according to the Society of Motor Manufacturers and Traders.

Big manufacturers are making long-term commitments to next-generation plants and technologies, and a key part of their strategy is to install mezzanines that maximise use of space.

Outstanding track record

Mezzanines suit ambitious businesses in the automotive supply chain and manufacturers using robotics to save time and costs. They are the most efficient way to future-proof factories for further expansion, without the expense and inconvenience of finding new premises.

Hi-Level Mezzanines has an outstanding track record in installing mezzanines for the automotive industry, working with Aston Martin, BMW, Jaguar Land Rover, Rolls-Royce and Toyota.

Both Labour and the Conservatives have promised investment in the sector to fuel growth. Labour’s sector deal for the automotive industry aims to produce two million electric cars and create 80,000 high-skilled jobs. It includes new battery factories with priority planning permission, support colleges to specialise in technical skills needed to build electric vehicles and ten-year funding cycles for automotive R&D, to match those given to aerospace.

The Conservatives have pledged £2bn investment in UK automotive ‘strategic manufacturing’ to support the manufacturing, supply chain and development of zero-emission vehicles.

Mike Hawes, SMMT Chief Executive, said: “This reflects the fact the UK automotive sector has the talent, the innovation and the determination necessary to thrive in the face of fierce global competition.”

Here are our 5 top benefits of mezzanines for the automotive sector:

- Mezzanines are a superb option for electric vehicle (EV) manufacturers expanding their operations. With EV production accelerating to meet net-zero targets and heavy investment underway, the automotive sector is on a high-growth trajectory coupled with the need to remain agile. Despite economic currents, global volumes of EV and hybrid models grew 35% year-on-year in 2023 to reach 14.2 million units, equating to a market share of 16.7%, up from 13.6% in 2022, according to Autovista24. Installing a single mezzanine or multiple tiers allows automotive businesses to make full use of existing vertical space as well as plan for future growth. At Hi-Level Mezzanines we currently have projects underway for automotive businesses that do just that.

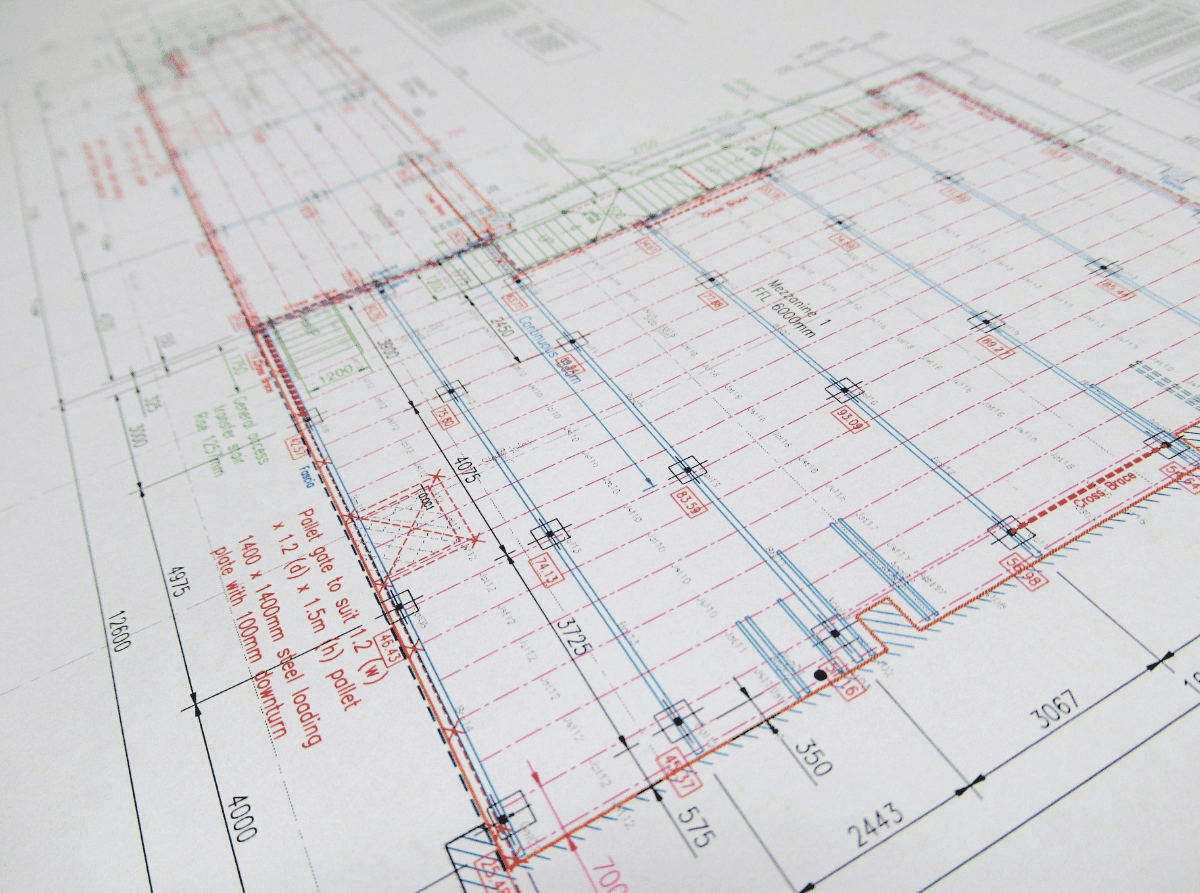

- Mezzanines are perfect for production facilities: an example is our work for Aston Martin, where we installed two single tier mezzanine floors with a project value of £1.8m. The first floor facilitates operations from leatherwork sewing to initial vehicle assembly, while the second floor accommodates assembly of the vehicle body before painting. The mezzanines needed to take a high-capacity one-ton point load, to give flexibility for the equipment layout. As well as manufacturers with small-volume, high-quality output such as Aston Martin, mezzanines are just as well suited to high-volume factories. Read more about mezzanines for manufacturing here.

- Mezzanines provide extra space for showrooms and storage: at Hi-Level Mezzanines we have created structures for a supercar showroom that featured a £20 million Maclaren, and mezzanines for an EV manufacturer to store parts from light bulbs to car doors.

- Every mezzanine is engineered to fit each client’s circumstances, and our starting point will always be to work out how much weight your ground slab can bear. For Jaguar Land Rover we designed and installed a composite concrete floor in the laboratory at the company’s R&D site. The requirement was for a very stiff floor, to prevent vibrations interfering with the tests going on above. Every mezzanine is also value-engineered by our in-house design team to reduce labour and material costs.

- Mezzanine floor tiles make zoning simple. The versatility of our structures means they can be used for workspaces, staff areas, canteens and walkways, for example. We have created a revolutionary Hi-Tile flooring system for mezzanines that uses robust interlocking 7mm textured PVC tiles. It is the most durable, cost-effective flooring on the market. It is easy to zone different areas, such as production, office and washroom facilities, with a range of colour options. Hi-Tile’s seamless interlocking joints, electrostatic resistance and anti-slip surface also make it the perfect partner for robotics in the automotive sector.

If you are considering installing a mezzanine and would like more information, contact us today at [email protected] or call 01730 237 190 .