Warehouse automation has emerged as one of the key trends in the 3PL sector as operators battle against the continuing capacity crunch, according to a new report.

Automation can help maximise efficient use of space and is identified as a crucial strategy in tech provider Extensiv’s 2023 State of the Third-Party Logistics Industry Report.

At Hi-Level Mezzanines we have witnessed this trend growing exponentially over the past three years, as our clients install mezzanines able to withstand the demands of robotics.

Revolutionising flooring for warehouse robots

This race to automate is why we have developed our unique robot-ready flooring Hi-Tile, revolutionising flooring for warehouse robots.

The 3PL industry study notes how nearly six in ten 3PL warehouses are running at more than 90% capacity: 39% are 90% to 100% full, while 20% are operating above 100% capacity.

“Given low vacancy rates and high rent costs for what little is available – not to mention the prohibitive costs of building new warehouse space for many smaller and regional 3PLs – warehouses will need to embrace creative solutions to expand their footprints,” it says. Combined with a tight labour market, this capacity crunch is undermining productivity.

Warehouse automation technologies

One way out is to implement warehouse automation technologies, the report suggests: “With most warehouses facing capacity and labour constraints, turning to automation to help increase spatial efficiency and reduce labour needs in the warehouse is a no-brainer.”

Automation therefore leads Extensiv’s trends for 2023, with one example being warehouse management systems (WMS) software.

Another example is advanced picking, which creates a 30% efficiency gain and up to 60% in time savings, according to the report.

To meet the demands of the booming global logistics automation sector, Hi-Level Mezzanines launched our innovative robot-ready flooring system at IWLEX in May.

Durable and cost-effective

Hi-Tile uses robust interlocking 7mm textured PVC tiles to create the most durable, cost-effective flooring on the market.

Its electrostatic resistance and anti-slip surface make it the perfect partner to robotics solutions. It is already in use by Geek Plus Robotics and with Locus’s Directed Picking technology.

Industry specialists have echoed the findings of the 2023 State of the Third-Party Logistics Industry Report. The global logistics automation market was valued at £30.16 billion and is expected to reach over £93.11 billion by 2027, according to UK Manufacturing, which credits the demand for industrial robots as driving much of that growth.

Hi-Level installations to date range from 200 to 9000m2 for warehousing, production, automation and robotics environments.

However, the 3PL report urges operators to get the balance right between machines and humans, with high-quality training for staff overseeing operations and performing value-added tasks. Investment is automation is a route to creating a new class of jobs rather than replacing employees, it points out.

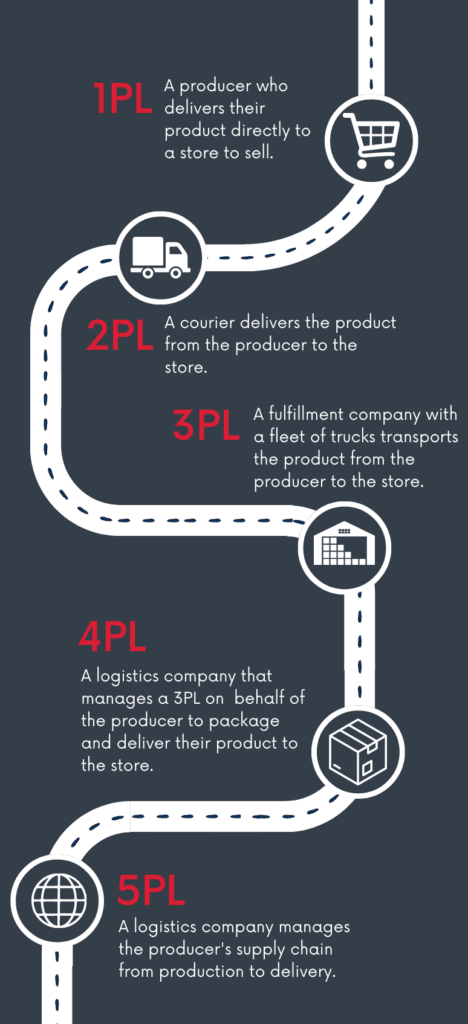

4PL – alarming competition or opportunity for profit?

Another trend identified in the report is the growth of the 4PL phenomena.“Fourth-party logistics (4PL) could end up being one of the biggest buzzwords in logistics in 2023,” it says.

On the one hand 4PL can be seen as alarming new competition in an already tough industry, but if 3PLs partner with 4PL networks or create their own 4PL networks there can be many benefits. These include giving clients faster and cheaper delivery, reducing carbon footprint, improving client satisfaction and increasing profitability, according to the report.

It highlights how the global 4PL market is expected to see massive growth from $63 billion in 2022 to $86 billion by 2027 (source: Statista).

Ready for 5PL

With 5PL now coming over the horizon, this handy graphic may help clarify the way ahead:

In a nutshell, a 5PL operator combines the transport and logistics services of a 3PL provider with the supply chain optimisation of a 4PL provider by using the latest technologies to manage a client’s entire network of supply chains.

And all can benefit from making the very best use of their space by installing mezzanines!

If you would like to find out more about Hi-Tile robot-ready flooring, please get in touch at [email protected] or call 01730 237 190.