Bill Somerton, Solutions Director at Bisham Consulting, shares his expertise.

As a leading Logistics director and Consultant, Bill has worked on projects around the world, from Europe to Thailand, Australia to the United States. He has come across many “elegant” solutions that don’t answer the “correct” question … so when it comes to installing a mezzanine, he has proven expertise as to what will and won’t work.

Bill has worked across multiple industries and varying scales of project from a garment supplier requiring 40,000 ft² up to sites of 600,000 ft². Sectors range from OEM equipment to auto parts, plumbing supplies, grocery, fashion, food services and tool suppliers. He recently completed a project for a 400,000 ft² site for a major retailer including five levels of mezzanine reaching 21m high in total.

With warehouses constantly challenged by a lack of operating space – whereas 20 years ago they were built tall so that goods could be stacked high and sent in bulk, today the priority is quick access, more orders of smaller size and increasing automation – mezzanines are the ready answer.

Key factors when planning a mezzanine

Logistics directors seeking to incorporate mezzanines into a project should take five factors into account, Bill says:

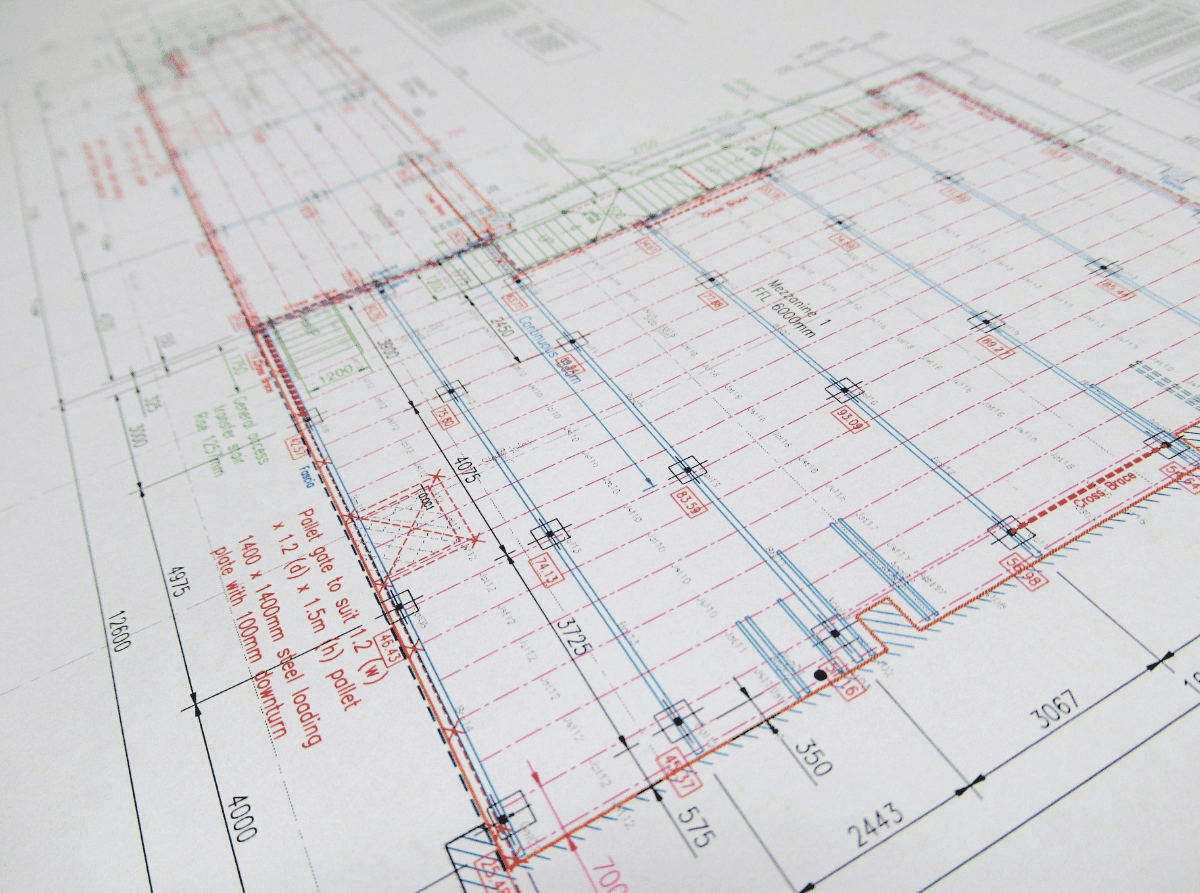

- There must be a workable grid (the space between the uprights supporting the mezzanine). The challenge is ensuring the floor of the building can take the weight. How wide the grid is will determine the load being put through the Mezzanine columns. Engaging a mezzanine provider early on is critical to create the best solution for column loading and grid size.

- Height between floors is the next key consideration, with 3m generally considered to be comfortable for workers. The ground floor may require additional clearance dependent on forklift requirements, all of which will determine floor depth and the number of levels installed.

- When warehouses include robotic operations the Logistics Director needs to work with the mezzanine supplier to ensure a suitable robot-ready floor surface is fitted, something robust enough to take the robots’ weight and hardwearing so that they will not gouge grooves into the floor. Hi-Level Mezzanines’ robot-ready flooring is a good example.

- Another essential factor is that decking can be damaged if not protected in the time between the mezzanine being installed and project completion. Lighting/Electrical – Heating & Ventilation and Sprinkler Installation teams and other M&E contractors can be working on the floors:; these typically require protective boards which are both expensive to fit and detrimental to the environment when disposed of. Ideally Logistics Directors choose a supplier with a decking solution that can be easily retrofitted when the build is almost complete.

- Nothing beats a mezzanine supplier with expertise and experience. Suppliers should be prequalified before selection, with references. Look for detailed experience and the right cultural fit. Working with mezzanine specialists such as Hi-Level Mezzanines, who have a 30-year track record, streamlines the whole process.

What Bill looks for in a working partnership

Flexibility – requirements often change, so it is vital to work with a partner with the versatility to deal with unforeseen changes to the brief.

Strong project management – strong coordination along with managing budgets and timescales is critical. Good communication with the logistics director and end client is very important.

Collaboration – a good supplier makes a logistics director’s job easier and provides a better result for the client. When the consultant and supplier work together, they can come up with the best solutions to suit every different project.

Expertise and experience

Bill recently completed a landmark project with Hi-Level Mezzanines and found it a very positive experience. “Hi-Level’s responsiveness and flexibility is refreshing,” he says. “Throughout the project, faced with supply chain issues they still delivered on budget and on time.”

He adds: “Hi-Level’s robot-compatible floor finish can be retrofitted and therefore avoids the need for floor protection thereby saving costs. and is a real USP for Hi-Level.

Hi-Level Mezzanines provides mezzanine floors of the highest quality in the industry, yet remaining competitively priced thanks to the expertise of our team of qualified structural engineers, innovative digital design process and advanced solutions.

For 30 years we have been creating space for amazing things to happen. Contact us today for more information at [email protected] or call 01730 237 190.